Special Furnace

Home > Product > Special Furnace

N2AF - 3RP N2 Atmosphere Multi-Furnace

※unit(mm)

| Heat zone | 200Φ X 400L |

|---|---|

| Uniformity zone | 160W X 10H X 370L(Top/bottom 2 stages, 3 Furnaces) |

| Temperature of use | 400℃ |

| Heating element | Radiant Pad Heater |

| Atmosphere | Nitrogen |

| Temperature control | POrogrammable PID Digital Control |

| Power | 220V, 3 phase, 23KVA |

| Cooling water | 5ℓ/min |

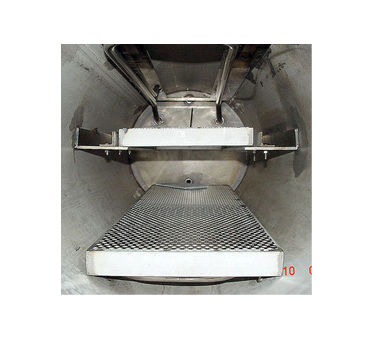

EDWF-1260 Elevating Type Degreasing Machine

※unit(mm)

| Heat zone size | 1260W x 640L x 550H |

|---|---|

| Heater | Kanthal AF |

| Temp | 320℃ +/-8℃ |

| Inlet gas | N2 + Air |

| Deodorization machine | 380V, 3 phase, 24KW |

| power | 380V, 3 phase, 115KVA |

Degreasing Machine

※unit(mm)

| Model name | DWF - 8 - 8 - 8 | DWF - 4 - 4 - 7 |

|---|---|---|

| Heat zone | 800W X 800D X 800H | 400W X 400D X 700H |

| Temperature of Use | 600℃ | 600℃ |

| Heating element | NCH - 1 | 316 stainless steel sheath heater |

| Atmosphere | Air | N2 |

| Temperature control | POrogrammable PID Digital Control | POrogrammable PID Digital Control |

| Power | 220V, 3 phase, 18KVA | 380V, 3 phase, 35KVA |

| After Burner | - Temperature of use: 800℃ - Heating element: Kanthal A1 - Temperature control : POrogrammable PID Digital Control |

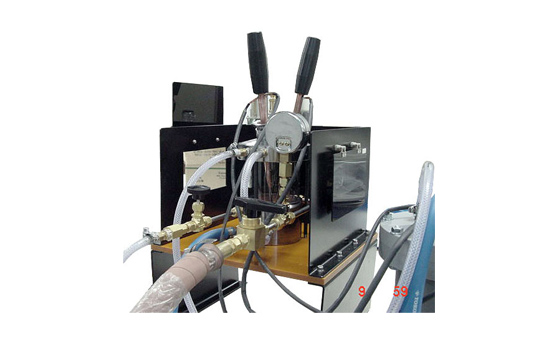

Tri Arc Furnace for Mass Production

※unit(mm)

| Temperature of Use | 2600℃ or higher |

|---|---|

| Atmosphere | Ar |

| Power | 150 KVA |

| Arc Power | 600 A |

Tri Arc Furnace for Experiment

※unit(mm)

| Temperature of Use | 2600℃ or higher |

|---|---|

| Atmosphere | Ar |

| Power | 150 KVA |

| Arc Power | 600 A |

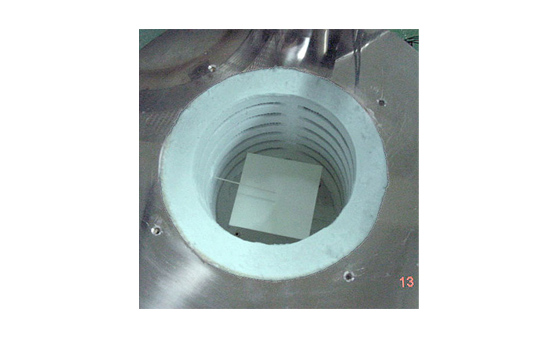

Single Arc Furnace

※unit(mm)

| Size of Chamber | 140Φ X 90H |

|---|---|

| Max temp | Higher than 3000℃ |

| Power | 300A DC |

| Compoenets |

|

| Accessory | 300A Power supply |