Our furnace for test

Home > Product > Our furnace for test

TNBF-6565 Baking Furnace (Double-sided Heater type)

※unit(mm)

| Heat zone | 650 x 650 x 600H ※Can be changed according to consumer needs |

|---|---|

| Max temp | 1500℃ ∼ 2900℃ |

| Degree of vacuum | Around 10(-2) torr ※When attaching a diffusion pump, around 10(-5) torr |

| Used Gas | H2, N2, Ar, HCl, Cl2 |

| Utility | Power 90KVA, Cooling water, Process Gas, Air |

| Optional items |

|

TNBF-9090 Multistage Heater Furnace

※unit(mm)

| Heat zone | 1000 x 1000 x 650H, 6단 ※Size and the number of stages can be changed according to consumer needs. |

|---|---|

| Max temp | 1500℃ ∼ 2900℃ |

| Degree of vacuum | Around 10(-2) torr ※When attaching a diffusion pump, around 10(-5) torr |

| Used Gas | H2, N2, Ar, HCl, Cl2 |

| Utility | Power 180KVA, Cooling water, Process Gas, Air |

| Optional items |

|

| Characteristic |

|

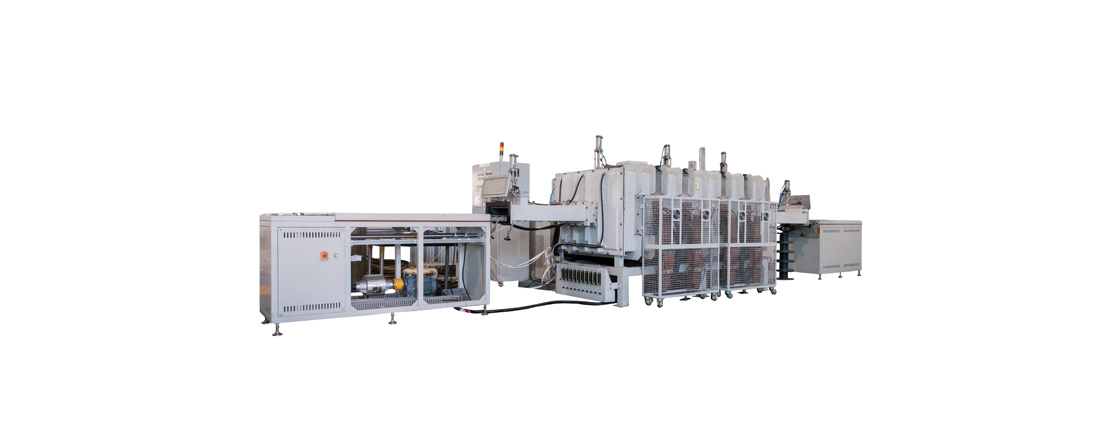

TNRST-2000 Pusher-style Square Continuous Furnace

※unit(mm)

| Heat zone | 2000L ∼ 8000L x 1000W x 70H ※Can be changed according to consumer needs |

|---|---|

| Max temp | 2400℃ ※Can be changed according to consumer needs |

| Heater | Graphite Rod Type Heater |

| Insulating material | Graphite molded insulating material |

| Rail | Graphite |

| Conveyor | Pursher or Roll to Roll method |

| Used Gas | N2, Ar |

| Utlity | Power 200KVA, cooling water, process gas, air |

| Purpose |

|

| Zone control method | Optical Pyrometer Control |

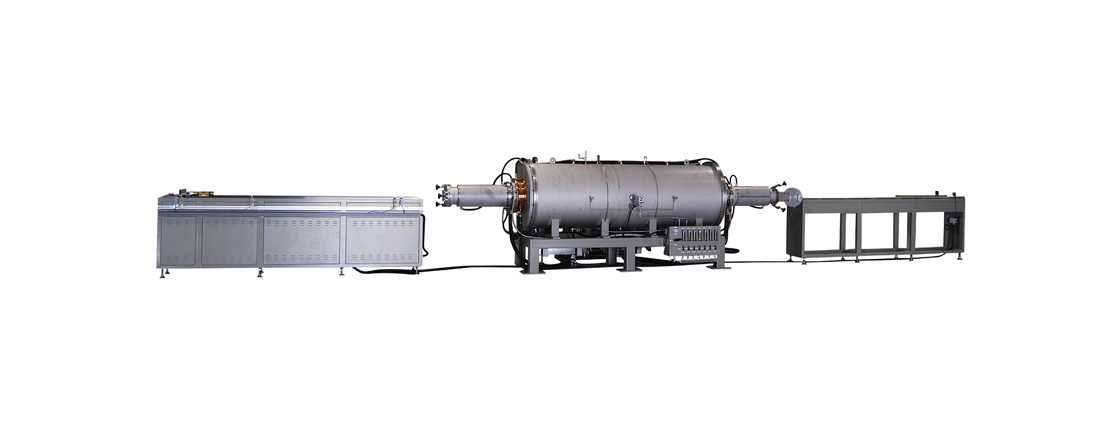

TNOST-7500 Pusher-style Round Type Continuous Furnace

※unit(mm)

| Heat zone | 260 Dia. x 7500L ※Can be changed according to consumer needs |

|---|---|

| Max temp | 2900℃ ※Can be changed from 1000 ~ 2900℃ according to consumer needs |

| Furnace body dimensions | 9900L x 1100W x 1100H |

| Furnace installation area | 23000L x 7000W x 3000H |

| Heater | Graphite Round Type Heater |

| Insulating material | Graphite molded insulating material |

| Rail | Gaphite |

| Used Gas | N2(Up to 2400℃), Ar |

| Utlity | Power 500KVA, cooling water, process gas, air |

| Purpose |

|

| Zone control method | Optimal Pyrometer Control |

TNMA-N1 (Patent) Multisgtage Multi-Atmosphere Furnace

※unit(mm)

| Heat zone | Consumer demand |

|---|---|

| Heater | Al2O3 Sheath Heater |

| Insulating material | Al2O3 molded insulating material |

| Atmosphere | Various gases such as air, N2, Ar, NH3, O2, etc. |

| Plate for loading samples | Al2O3 Plate |

| Characteristics |

|